Powder Coating

About Powder Coating

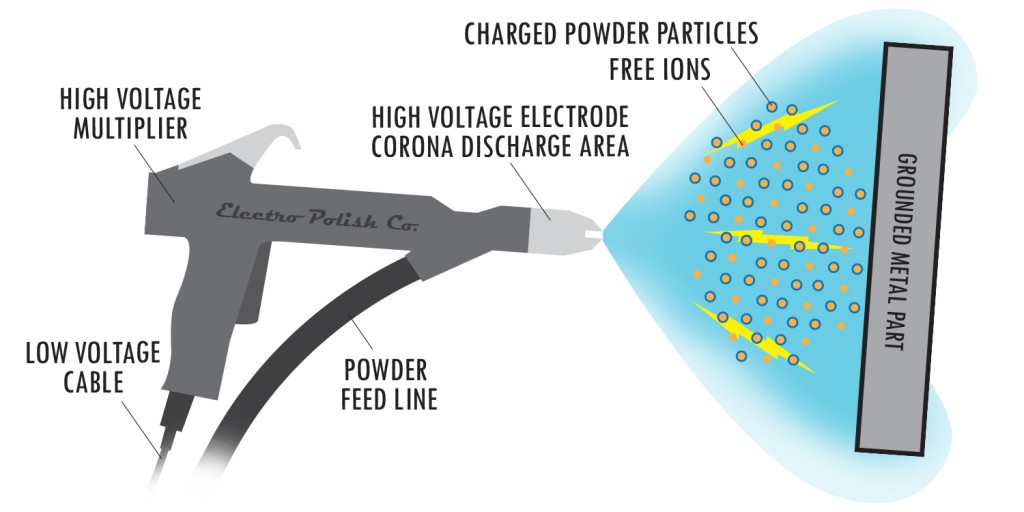

Powder coating is applied as a free-flowing, dry powder, electrostatically and then cured under heat to allow it to flow and form a “skin”. Powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, like household appliances, aluminium extrusions, hardware, and automobile, bicycle, boating parts. Newer technologies allow other materials, such as MDF (medium-density fibreboard), to be powder coated using different methods.

Powder coating requires a completely clean surface for optimal adhesion. Electro Polish uses several cleaning methods for powder coat prep depending on size, material, cleanliness, etc. Because we do so many metal finishes in house we have cleaning methods for any metal at our disposal. Our main method utilizes a hot power wash with a phosphate coating followed by a quick dry in the oven.

Once part has been prepped and cleaned, it is placed in the powder coating booth and grounded with a clamp. This allows the electrostatically charged powder to adhere to the part when being applied. After the part is fully coated, it is placed in an oven at 350-400 degrees F. After getting up to temperature, the part is left in for the cure time specified by the powder manufacturer.

We carry a variety of powders for materials in a variety of applications. If we don’t have it in stock, we’ll track it down for you. If you don’t know what kind of powder would be best to use for your project, we can help find it for you.

This simple infographic shows the powder coating process as it happens. Where regular paint will over spray, causing waste and mess, powder wants to attach itself to the grounded part as much as it can. There will still be some waste, naturally, but it can be swept up or even reclaimed for reuse.

Our Process

The metal part is hung strategically so entire part can be seen, reached, cleaned and coated with minimal bare marks due to hanging/racking. We prefer the customer specify where appropriate to hang from, otherwise we will find the best way. Part will be hung on a mobile rack with wheels, able to carry up to 500 lbs. The rack is wheeled into the power wash/steam clean booth and washed down with degreaser. It is then power washed with hot water. Once part has dried, it’s ready for powder!

Rack is wheeled into the powder coating booth. Once grounded, it’s ready to shoot. Shooting from the back of the booth, moving in the processor sprays evenly the entire part. Some areas are harder to coat than others, so techniques and different gun settings are used to achieve complete coverage. Once part is totally coated it is ready for baking!

Rack is wheeled from the booth into the oven. Most powder coatings cure at 350-400 degrees F. Once part has baked for required amount of time, rack is wheeled out to cool. Parts are un-racked and packed for shipping or pick up.

What you can do

Make sure part is as clean as possible. We will clean to the best of our ability, but excess cleaning may result in extra charges. We recommend a sandblast, particularly for steel parts. We do not sandblast, so they must be done elsewhere prior to arrival if needed. For best finish, sandblasting is a good idea but not necessary.

We do require parts to not have any rust on them. Powdercoating over rust will NOT prevent further rust. It will ONLY get worse under the coating, creating separation between the powder coat and the part resulting in flaking. If your parts have rust, we recommend getting them sand blasted prior to bringing them to us.

Powder adhesion is only as good as the surface it is applied to. This is why proper prep is so important. Understand that we cannot guarantee proper powder adhesion if we are going over a pre-existing coating like paint or another powder. We will and have done this, and as long as it’s a cosmetic/appearance finish, it’s an acceptable procedure.

Got A Job For Us?

Solid, long-term customer relationships are the backbone of our company.

From the moment you contact us to delivery of your finished piece, our focus is on excellent results and diligent customer service.